Range: Includes a variety of range options, such as 0 ~ 0.6MPa, -95 ~ 1.6MPa, -95 ~ 1.0MPa, -95 ~ 2.5MPa, 0 ~ 2.5MPa, -95 ~ 4MPa, 0 ~ 4MPa, 0 ~ 6MPa, 0~25MPa and a specific range such as -95 ~ 25bar.

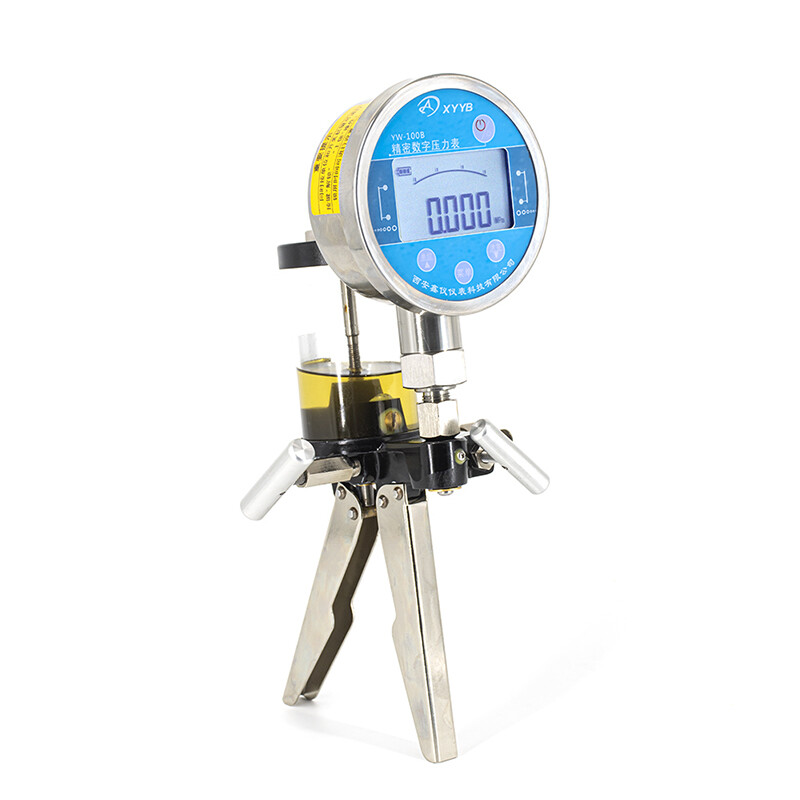

Hand-held pressure calibration pumps usually have a small and lightweight design. For example, some models weigh only about 0.8kg, and compared to traditional large pressure pumps, operators can easily carry it to a variety of complex or restricted working environments, such as small equipment interiors, high-altitude work platforms, or remote work sites. This feature greatly improves work efficiency and reduces the cost and time consumption of equipment handling. This is because in many practical work scenarios, large equipment is difficult to reach the work site, and hand-held pressure calibration pumps can easily solve this problem. Hand-held pressure calibration pumps are widely used in many fields, including but not limited to ships, chemicals, power plants, petroleum and petrochemical, science and technology, steel, engineering, etc. It can not only be used to verify pressure gauges, pressure transmitters, pressure switches and other pressure instruments, but also can be used as a pressure benchmark in the laboratory and pressure instrument production process.

Pressure regulation mechanism: The use of advanced pressure regulation mechanism, can quickly respond to operating instructions, so as to achieve accurate control of pressure. This means that whether you need a quick boost to test your equipment's pressure resistance or you need to fine-tune the pressure to meet specific process requirements, the hand-held pressure calibration pump is easy to handle. For example, in the pressure test of the automobile brake system, the pressure value needs to be precisely controlled to ensure the safety of the brake system, and the hand-held pressure calibration pump can well meet this demand.

Hand clamp pressure and boost fast: Some hand-held pressure calibration pumps use the hand clamp pressure mode, which can make the pressure rise quickly. In some scenarios that need to quickly establish a pressure environment for testing, such as emergency equipment troubleshooting, rapid voltage boost can save a lot of time and improve work efficiency.

Imported seals and good pressure holding effect: equipped with imported seals, to ensure that the equipment has a good pressure holding effect. In the process of pressure calibration, stable pressure maintenance is very important, if the pressure holding effect of the equipment is not good, it may lead to inaccurate calibration results.

Stainless steel parts and long service life: The use of stainless steel parts enhances the durability of the equipment, thus extending the service life of the equipment. This reduces the frequency of equipment replacement and reduces the cost of use in the long-term industrial use process.

Chat Online