The steps for using the multifunctional process calibrator are as follows:

1.Preparation work

Check whether the multifunctional process calibrator is damaged or has other abnormal conditions, and confirm whether the power supply and voltage are compatible. Choose the appropriate calibration module, the multifunctional process calibrator has multiple calibration modules to choose from.

2.Connected Device

Connect the multifunctional process calibrator to the device to be verified, and choose different interface methods according to different devices. Commonly used ones include handheld interfaces, clip on connectors, etc

3.Set verification parameters

Set corresponding calibration parameters based on the parameters of the device to be verified, such as calibration range, calibration point count, calibration accuracy, etc. When setting up, attention should be paid to selecting appropriate calibration modes, including manual mode and automatic mode.

4.Start verification

After entering the verification state, select the corresponding calibration point for verification according to the prompts of the multifunctional process calibrator. When conducting calibration, it is necessary to follow the calibration procedures of the equipment to ensure accurate and reliable test results.

5.Complete verification

After the verification is completed, the multifunctional process calibrator will automatically calculate the verification result. Save the verification data to the memory or external storage device of the multifunctional process calibrator for future reference and analysis.

The functions and application scenarios of multifunctional process calibrators:

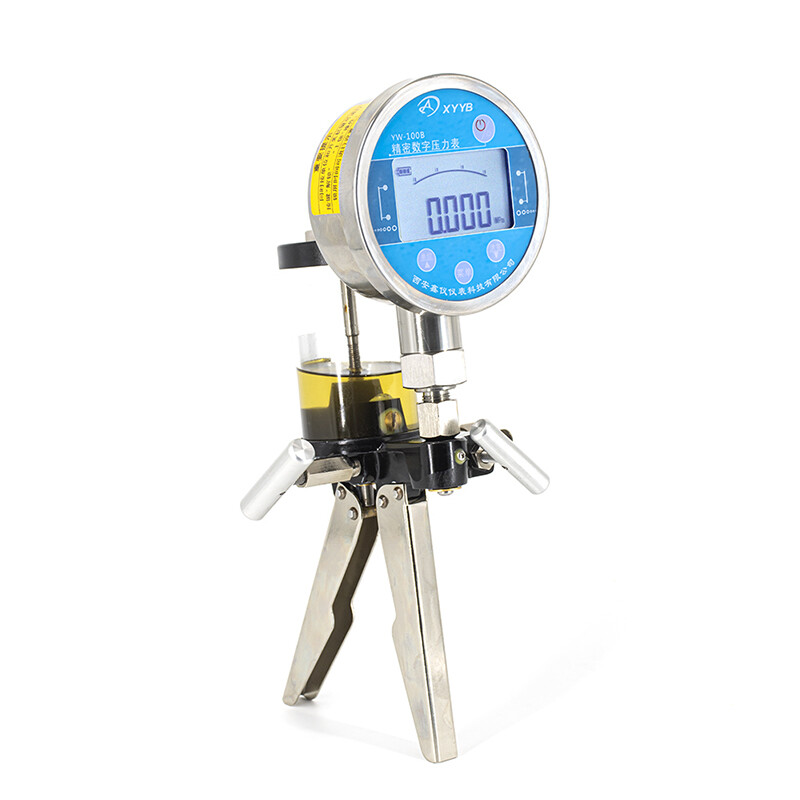

Multi functional process calibrators are instruments and equipment used for testing, calibrating, inspecting, and diagnosing various on-site instrument signals and control systems. It can detect signals such as pressure, temperature, flow rate, and resistance in instruments, and is widely used in fields such as chemical engineering, metallurgy, power, and light industry.

Specific functions include direct current voltage (DCV) measurement and output, alternating current voltage (ACV) measurement, frequency measurement and output, resistance measurement and output, thermocouple and thermal resistance measurement, etc.

Precautions for use:

During use, safety should be taken into account to ensure that equipment and personnel are protected. For hazardous equipment such as high pressure and high temperature, corresponding safety measures should be taken before calibration.

When using a multifunctional process calibrator, one should avoid immersion in water, moisture, heat, or use in harsh environments such as vibration, dust, and corrosion to ensure the stable operation of the equipment.

During calibration, it is necessary to strictly follow the calibration procedures of the equipment to avoid errors caused by misoperation or improper operation.

Contact

Chat Online