Products

Contact Us

Get A Quote

Recommend

In the laboratory or measuring room, it is generally used with a precision pressure gauge (higher accuracy can reach 0.25 level) to detect ordinary pressure gauges (accuracy of 1.6 or 2.5).

The pressure gauge interface is generally M20×1.5 external thread, and the pressure gauge checker’s interface is M20×1.5 (with M14×1.5)

Product Description

Overview:

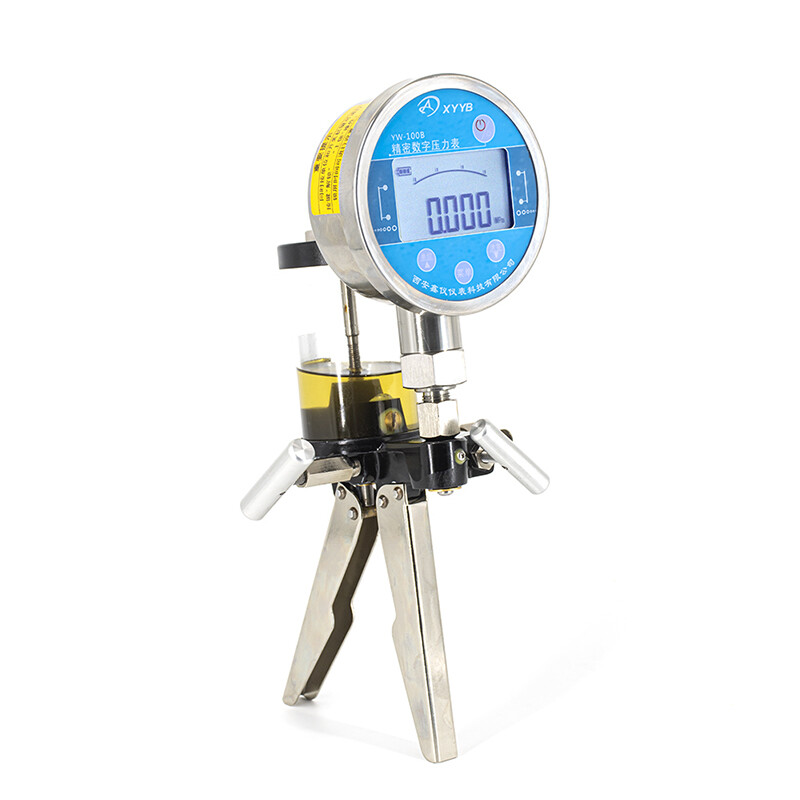

The pressure gauge calibrator is also called a pressure gauge calibration pump. The principle of the pressure gauge calibrator is to increase the pressure of the piston rod movement, so as to achieve the purpose of pressure.

The pressure gauge calibrator is a pressure source used to test general pressure gauges, the test pressure can reach 60MPA, and the test vacuum degree can reach -0.08MPA.

In the laboratory or measuring room, it is generally used with a precision pressure gauge (higher accuracy can reach 0.25 level) to detect ordinary pressure gauges (accuracy of 1.6 or 2.5).

The pressure gauge interface is generally M20×1.5 external thread, and the pressure gauge checker's interface is M20×1.5 (with M14×1.5).

Model: YW-6/60

Type:Hydralic Pressure

Range:-0.082~6Mpa/60Mpa

Weight:15Kg Minimum

Adjustable:0.1Mpa

Medium:Transformer Oil Medicinal Castor Oil

Install:

1. The calibrator should be placed on a workbench that is easy to operate and must be kept level.

2. The working environment temperature of the calibrator is +20±10℃, and the surrounding air must not contain corrosive gas.

3. The calibrator should not be shaken; a rubber pad should be placed on the workbench.

4. Before use, first clean the calibrator pipeline with gasoline, and then fill the oil cup with the pressure medium. Rotate the handwheel of the hand-operated screw pump to check whether the oil circuit is unobstructed; if there is no problem, install the precision pressure gauge and the pressure gauge to be calibrated.

use:

5. Operation steps:

When checking the pressure gauge:

(1) Open the oil cup valve and turn the handwheel to the left to fill the cylinder of the hand pump with oil.

(2) Close the oil cup valve, open the valve, and then turn the handwheel to the right to compress the oil, so that the oil pressure acts on the pressure gauge, and the inspection can be carried out according to the indicated values of the two gauges.

When checking the vacuum gauge:

(1) Clear the pressure medium inside the calibrator.

(2) Close the valve, open the oil cup valve, and screw all the hand pump screws into the cylinder.

Message

Products Recommended

Chat Online