Products

Contact Us

Get A Quote

Recommend

Product Description

Specifications

1 Name: Floating Ball Pressure Gauge

2 Model Specifications:

Y047 (0.001 ~ 0.25) MPa commonly used

Y055 (0.005 ~ 0.6 )MPa

3 Accuracy: Class 0.05

4 Weight: 304 non-magnetic stainless steel

Overview

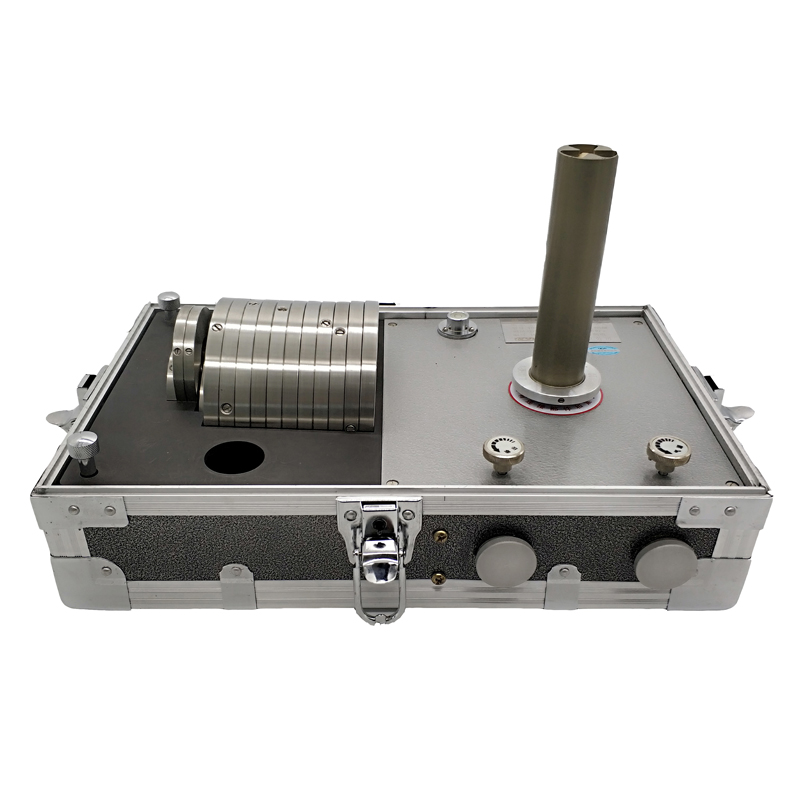

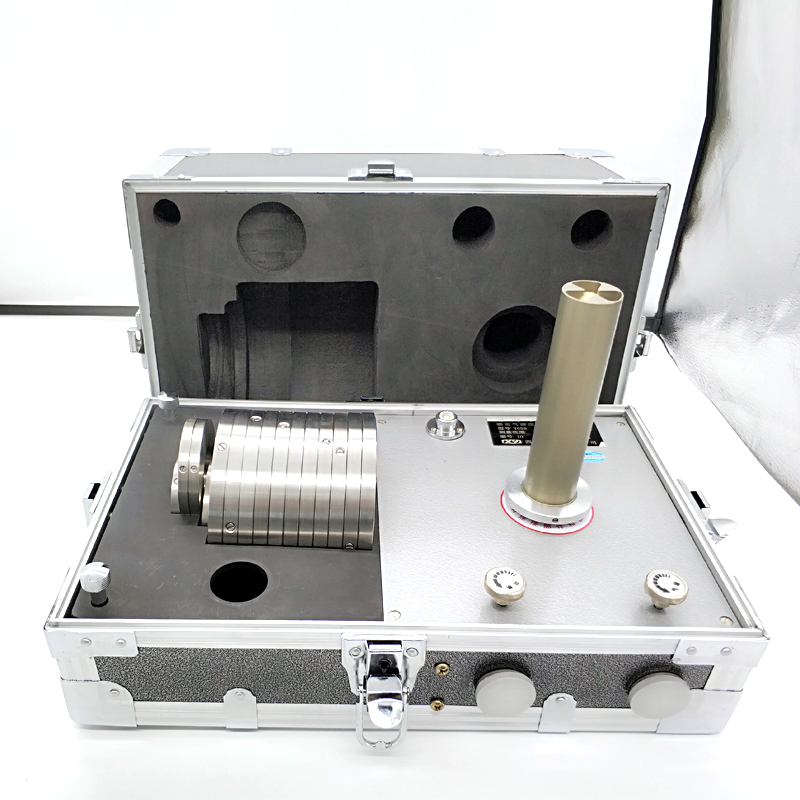

The float ball pressure gauge is a pneumatic load pressure gauge that uses compressed air or nitrogen as the pressure source, and takes the pressure action area of the lower part of the sphere when the precision float is in working state as the effective area of the float. As shown in Figure 1, the precision float is placed inside the cylindrical nozzle, the special weight acts on the top of the sphere through the weight holder, and the air pressure in the nozzle acts on the lower part of the sphere, causing the float to float in the nozzle. When the gravity generated by the special weight of known mass is balanced with the force of the air pressure, the float pressure gauge will output a stable and accurate pressure value.

Principles

Compressed air or nitrogen enters the lower part of the sphere through the flow regulator and is discharged into the atmosphere through the gap between the sphere and the nozzle. The pressure created in the lower part of the sphere lifts the sphere together with the weights, and when the exhaust gas flow equals the flow from the regulator, the system is in equilibrium. At this time, the sphere will float to a certain height, and the pressure action area (ie, the effective area of the floating ball) at the bottom of the sphere will also be fixed. Since the pressure in the lower part of the sphere passes through the pressure stabilizer as the output pressure, the output pressure will be proportional to the weight load. When adding or subtracting weights on the weight frame of the floating ball pressure gauge, the balance state of the measuring system will be changed, causing the floating ball to drop or rise, the flow rate of the gas discharged into the atmosphere will change immediately, and the pressure at the lower part of the floating ball will change. If it changes, the flow regulator will timely and accurately change the inflow of the gas, so that the system will re-balance, keep the effective area of the float constant, and maintain the proportional relationship between the output pressure and the weight load. The high accuracy of the float pressure gauge is ensured.

Advantages

Compared with piston pressure gauges, float pressure gauges have the following characteristics:

1. The float pressure gauge has a built-in automatic flow regulator. After adding or reducing the weight, you can get the accurate output pressure without any operation.

2. The floating ball does not drop when working, and can output accurate pressure signals continuously and stably;

3. The float pressure gauge has the function of self-regulation of flow, and its accuracy has nothing to do with the technical level of the operator;

4. When the instrument is working, the air flow causes the floating ball to be suspended in the nozzle, and the ball and the nozzle are in a non-contact state. Its low friction, good repeatability and high resolution are the unique characteristics of floating ball pressure gauges;

5. During the working process, the air flow can continuously self-clean the floating ball, which ensures the high reliability of the instrument. The chassis of the float pressure gauge is installed on a box-type base (as shown in Figure 2), and the chassis is the work surface of the pressure gauge. The level gauge and the control valve are arranged on it, and the air source interface is arranged on the side for the connection between the pressure gauge and the pressure source.

Technical parameters

Y047 type float pressure gauge

Weight racks: 0.001Mpa and 0.005Mpa weight racks each

Output pressure range: 0.001~0.25MPa

Y055 type float pressure gauge

Weight rack: one weight rack of 0.005Mpa

Output pressure range: 0.005~0.6MPa

Y055A type float pressure gauge

Weight rack: one weight rack of 0.005Mpa

Output pressure range: 0.005~0.4MPa

Placement

The float pressure gauge should be placed in an environment where the temperature is as close as possible to 20°C, the humidity is 10-75%, the surrounding air flow is not large, and there is no corrosive medium and no vibration source. The table should be stable and easy to operate.

Connection

The float ball pressure gauge must be connected to the gas source and the instrument under test with the connecting pipe attached to the pressure gauge. When connecting, the knurled nut on the joint must be tightened to prevent the joint from coming off or leaking during operation. Float pressure gauges have clean, dry and oil-free requirements for their pressure sources. If the pipeline compressed air cannot meet the purification requirements, it is recommended to use bottled nitrogen or connect the pipeline compressed air to the float pressure gauge through a gas purification device.

Operation

When operating the float pressure gauge, the air source pressure should be adjusted first, then the air source valve and the output valve should be opened and the weight holder should be placed on the float ball. After the float floats, the pressure gauge will output a pressure value (0.001MPa or MPa or 0.005MPa) marked on the weight rack. One by one, increase or decrease the weight of the required pressure value on the weight frame according to the requirements of the instrument under test. When the float floats again, the pressure gauge can output the required calibration pressure.

Operation Precautions

1. It is not advisable to increase or decrease the weight too much at one time;

2. It is not necessary to rotate the weight of the float pressure gauge, too much rotation will affect the accuracy of the instrument;

3. After the detection process is completed, remove the weight, close the air source valve of the float pressure gauge, and then remove the instrument to be calibrated. The instrument under test cannot be removed under pressure to avoid impacting the floating ball;

4. The output pressure value of the float pressure gauge is the sum of the added weight and the pressure value indicated on the weight rack, and the error of the output pressure value does not exceed ±0.05% of the value. When the output pressure value is less than 10% of the upper limit value of the pressure gauge, the error does not exceed ±0.05% of the 10% upper limit value.

Daily maintenance

1. Keep it clean

Before using the float ball pressure gauge, check the cleanliness of the float ball and nozzle. If the cleanliness is too low, the output accuracy of the pressure gauge will be affected. The float and nozzle should be cleaned frequently with carbon tetrachloride or alcohol and dried with clean soft silk. When cleaning, gently unplug the nozzle from the pressure gauge by hand, and do not drop the floating ball when unplugging. When installing the nozzle, pay attention to the mark on the outer cylinder of the nozzle, and it must be installed in the positive direction. When loading and unloading, the nozzle can be turned gently to overcome the friction of the "O"-shaped sealing ring; before the float pressure gauge is used, a cleanliness inspection can be carried out as follows: open the air source valve, close the output valve, and put it on the float ball. Put a certain number of weights, when the float floats, the clean float and nozzle can rotate flexibly. After turning the weight lightly, it should be able to maintain a long continuous rotation time.

2. Leak Check

The leakage of the output connection pipeline of the float pressure gauge or the instrument being calibrated will affect the calibration accuracy. Leak detection can be carried out as follows: open the output valve, add weights to the weight rack of the pressure gauge, and make the pressure indicated by the calibrated instrument reach the specified value. Then close the output valve. If the indication of the instrument being calibrated can keep still, it can be considered that there is no leakage between the float pressure gauge and the instrument under test.

Influence and Correction of Gravitational Acceleration of Float Pressure Gauge

Under normal circumstances, the weight of the float pressure gauge is manufactured according to the standard acceleration of gravity (g=9.80665m/s2). When the gravitational acceleration at the place where the float pressure gauge is used is different from the standard gravitational acceleration, the actual value of the output pressure of the float pressure gauge can be calculated by the following formula:

float pressure gauge

Where p ── the actual value of the output pressure of the ground used (MPa)

g ── the gravitational acceleration of the place of use (m/s)

9.80665 ─ Standard acceleration of gravity (m/s),

p(a)── the sum of the added weight and the pressure value indicated on the weight rack (MPa)

Message

Products Recommended

Chat Online